-

Bruno NacimientoGracias por su continua ayuda y apoyo para proporcionarnos productos de alta calidad y asequibles.

Bruno NacimientoGracias por su continua ayuda y apoyo para proporcionarnos productos de alta calidad y asequibles. -

Ehsan Salmari fue el primero.La respuesta rápida y la actitud profesional hacen que nuestra cooperación sea más fluida.

Ehsan Salmari fue el primero.La respuesta rápida y la actitud profesional hacen que nuestra cooperación sea más fluida.

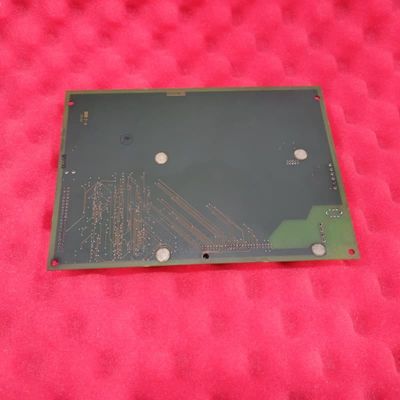

GE DS200ADGIH1A Tarjeta de Interfaz Auxiliar Mark V 100mm x 200mm

Éntreme en contacto con gratis las muestras y los vales.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

skype: sales10@aixton.com

Si usted tiene alguna preocupación, proporcionamos ayuda en línea de 24 horas.

x| Nombre | GE200ADGIH1A Mark v Board de interfaz auxiliar | ID de producto | Se aplicará el procedimiento siguiente: |

|---|---|---|---|

| Serie | Mark V | Ancho de redes de productos | 100 mm |

| Altura de la red de productos | 200 mm | Profundidad/longitud de la red del producto | 330 mm |

| Garantía | 1 año | Peso de la red del producto | 2 kg |

| Resaltar | Tarjeta de interfaz GE Mark V,Tarjeta auxiliar de control de turbina,Tarjeta de interfaz GE DS200ADGIH1A |

||

| Atributo | Valor |

|---|---|

| Nombre | GE DS200ADGIH1A Mark V Tarjeta de Interfaz Auxiliar |

| ID del Producto | DS200ADGIH1A |

| Serie | Mark V |

| Garantía | 1 Año |

| Dimensiones (Ancho × Alto × Profundidad) | 100mm × 200mm × 330mm |

| Peso | 2kg |

La GE DS200ADGIH1A es una Tarjeta de Interfaz Auxiliar dedicada, diseñada exclusivamente para el sistema de control Mark V de GE, ampliamente utilizado en aplicaciones de control de turbinas de gas, turbinas de vapor y generadores. Su función principal es servir como puente entre el controlador principal del sistema Mark V y los dispositivos auxiliares, facilitando la transmisión confiable de señales y la integración de componentes periféricos en el bucle de control.

Diseñada según los estándares industriales de GE, soporta el procesamiento de señales de entrada/salida (I/O) auxiliares, incluyendo el acondicionamiento, aislamiento y conversión de señales analógicas/digitales a formatos compatibles con la unidad de control central del Mark V. Esto asegura una comunicación fluida entre los sistemas auxiliares críticos y la lógica de control principal de la turbina/generador.

Físicamente, presenta terminales etiquetados, conectores y posiblemente indicadores de estado para facilitar el cableado, la resolución de problemas y las comprobaciones operativas en tiempo real. La instalación requiere personal capacitado para seguir las directrices del sistema Mark V y mantener la compatibilidad y la seguridad. Como un componente clave de la interfaz auxiliar, mejora la flexibilidad del sistema Mark V, asegurando que todas las funciones auxiliares se alineen con la estrategia de control principal para una operación estable y eficiente de la turbina/generador.