Todos los productos

-

Bruno NacimientoGracias por su continua ayuda y apoyo para proporcionarnos productos de alta calidad y asequibles.

Bruno NacimientoGracias por su continua ayuda y apoyo para proporcionarnos productos de alta calidad y asequibles. -

Ehsan Salmari fue el primero.La respuesta rápida y la actitud profesional hacen que nuestra cooperación sea más fluida.

Ehsan Salmari fue el primero.La respuesta rápida y la actitud profesional hacen que nuestra cooperación sea más fluida.

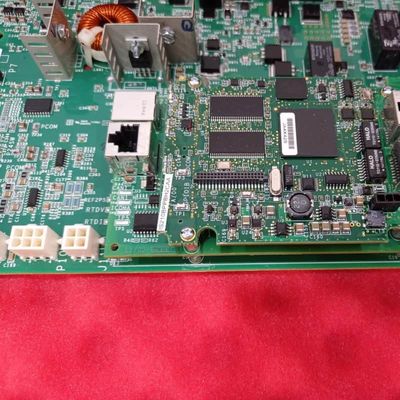

Módulo de control de paso de viento GE IS215WEPAH2AB para turbinas Mark VI

Éntreme en contacto con gratis las muestras y los vales.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

skype: sales10@aixton.com

Si usted tiene alguna preocupación, proporcionamos ayuda en línea de 24 horas.

xDatos del producto

| Nombre | Modulo de control del eje de paso del viento no CANBus | ID de producto | IS215WEPAH2AB |

|---|---|---|---|

| Peso de la red del producto | 2 kg | Serie | Marcos VI |

| Ancho de redes de productos | 100 mm | Altura de la red de productos | 200 mm |

| Profundidad/longitud de la red del producto | 330 mm | Garantización | 1 año |

| Resaltar | Módulo de control de paso de turbina GE Mark VI,Módulo de control de turbina eólica con garantía,Módulo de turbina GE IS215WEPAH2AB |

||

Descripción de producto

GE IS215WEPAH2AB Módulo de Control del Eje de Paso de Viento no CANBus

Especificaciones del Producto

| Atributo | Valor |

|---|---|

| Nombre | GE IS215WEPAH2AB Módulo de Control del Eje de Paso de Viento no CANBus |

| ID del Producto | IS215WEPAH2AB |

| Peso Neto del Producto | 2kg |

| Serie | Mark VI |

| Ancho Neto del Producto | 100mm |

| Altura Neta del Producto | 200mm |

| Profundidad/Longitud Neta del Producto | 330mm |

| Garantía | 1 Año |

Descripción General del Producto

El GE IS215WEPAH2AB es un Módulo de Control del Eje de Paso de Viento no CANBus de alta fiabilidad diseñado para la gestión avanzada de turbinas eólicas dentro del sistema de control Speedtronic Mark VI de GE. Diseñado para optimizar los ángulos de paso de las palas, asegura una captura eficiente de energía, la reducción de la carga y las capacidades de parada de emergencia, fundamentales para las operaciones de parques eólicos terrestres y marinos.

Como componente central de la arquitectura Mark VI, el módulo se integra perfectamente con las placas de terminales y los sistemas de control para ofrecer monitorización y actuación en tiempo real. Soporta los protocolos de comunicación IONet y UDH para un intercambio de datos robusto con el sistema de control principal de la turbina, eliminando la dependencia de CANBus mientras mantiene un rendimiento determinista y de alta velocidad. Con un enfoque en la seguridad y la durabilidad, cuenta con procesamiento triple redundante y recubrimiento de conformación para soportar condiciones ambientales adversas, incluyendo temperaturas extremas, humedad y vibraciones mecánicas.

Características Clave

- Comunicación No-CANBus: Utiliza IONet y UDH para una transmisión de datos segura y de alta velocidad, asegurando la compatibilidad con los sistemas Mark VI de GE y las redes de control de turbinas más amplias.

- Triple Redundancia: Implementa una arquitectura de votación 1oo3 para minimizar los fallos de un solo punto, proporcionando un funcionamiento continuo incluso durante fallos de componentes.

- Control de Precisión: Gestiona los ángulos de paso de las palas con tiempos de respuesta sub-milisegundos, optimizando la eficiencia aerodinámica y protegiendo contra eventos de sobrevelocidad a través del control directo de servomotores y solenoides.

- E/S Flexible: Soporta entradas/salidas digitales y entradas analógicas, permitiendo una monitorización completa de la dinámica de la turbina.

- Resistencia Ambiental: El recubrimiento de conformación y los componentes de grado industrial aseguran un funcionamiento fiable en temperaturas que oscilan entre -40 °C y +70°C, con resistencia al polvo, la humedad y la niebla salina.

- Cumplimiento de Seguridad: Alineado con los estándares IEC 61508 SIL 2, se integra con la cadena de seguridad de la turbina para ejecutar comandos de paso descendente de emergencia, asegurando paradas a prueba de fallos.

- Capacidades de Diagnóstico: Los LEDs del panel frontal y las autocomprobaciones integradas permiten la detección rápida de fallos, mientras que los diagnósticos remotos a través de IONet facilitan el mantenimiento predictivo y reducen el tiempo de inactividad.

Productos recomendados